WD01X21740 Bracket: Secure Countertop Dishwasher Mount Guide

Introduction: Why the Right Mounting Bracket Matters

Selecting the correct mounting bracket for a countertop dishwasher is a practical decision with measurable effects on day-to-day performance. A dedicated bracket secures the appliance to the underside of a countertop, limiting movement that can affect spray coverage, noise generation, door alignment, and the longevity of seals and fasteners. Household size, kitchen layout, and usage frequency shape priorities: small households or apartment kitchens often prioritize compact installations and noise control, while busier households may emphasize durability and ease of access for maintenance. Countertop materials such as granite or quartz demand specific load-distribution and fastening approaches to avoid surface damage. Expectations around cleaning performance, noise sensitivity, and water- or energy-efficiency are primarily driven by the dishwasher’s engineering, but mounting hardware like the WD01X21740 influences vibration damping and alignment, which can indirectly affect spray arm coverage and drying consistency. The right bracket helps maintain intended appliance geometry and reduces factors that can degrade wash and dry results over time.

Quick Overview

| Feature | Details |

|---|---|

| Product type | Replacement countertop dishwasher mounting bracket (accessory) |

| Compatible dishwasher type | Countertop dishwashers compatible with specified GE model numbers |

| Capacity / place settings | N/A — accessory part; capacity depends on the dishwasher model |

| Wash cycles / cleaning tech | N/A — bracket does not alter wash cycles |

| Drying method | N/A — bracket does not affect internal drying system |

| Noise level rating | N/A — bracket has no published acoustic rating; intended to reduce vibration-related noise |

| Energy / water certifications | N/A — accessory part does not carry energy certifications |

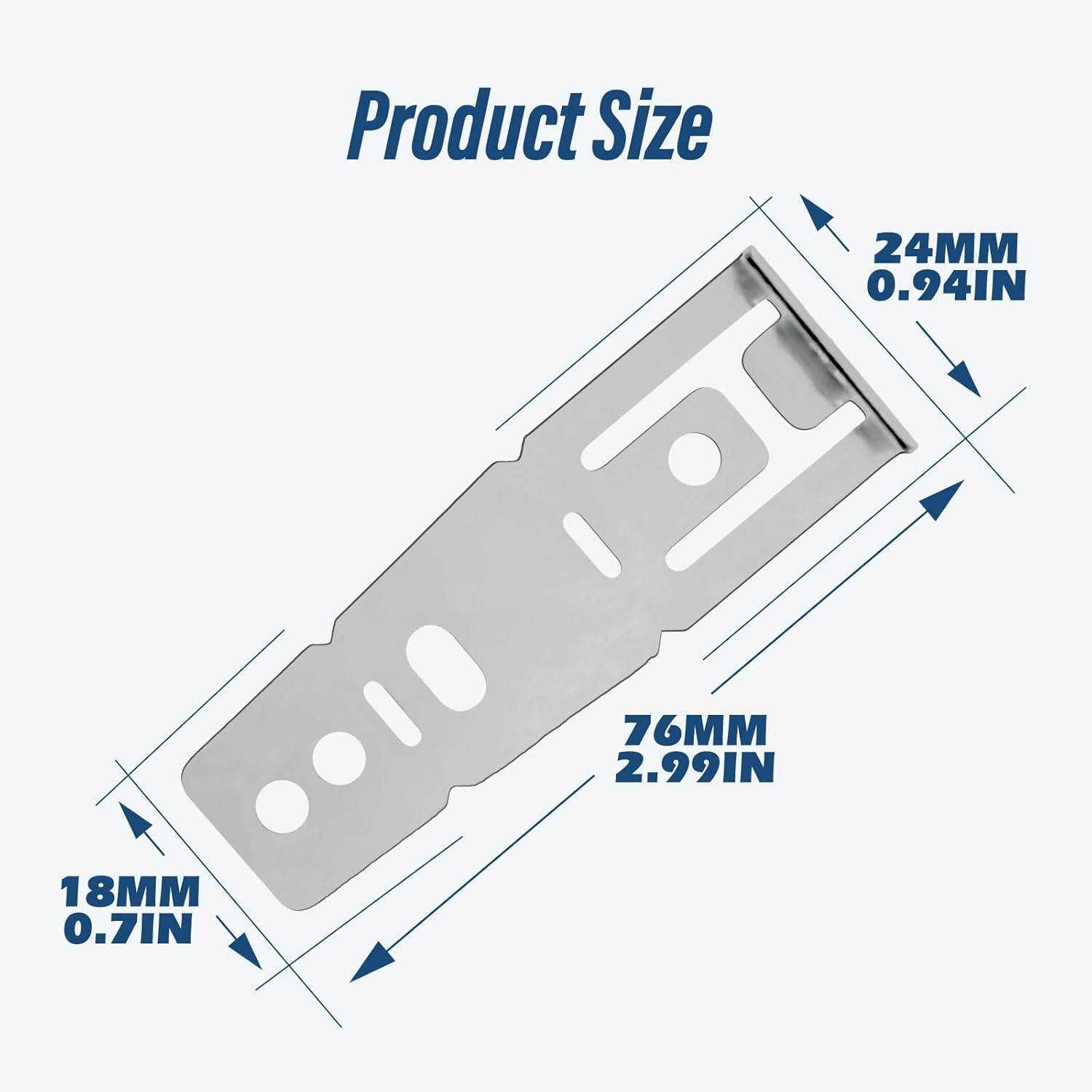

| Dimensions | 4.33 x 4.13 x 0.69 inches (bracket assembly) |

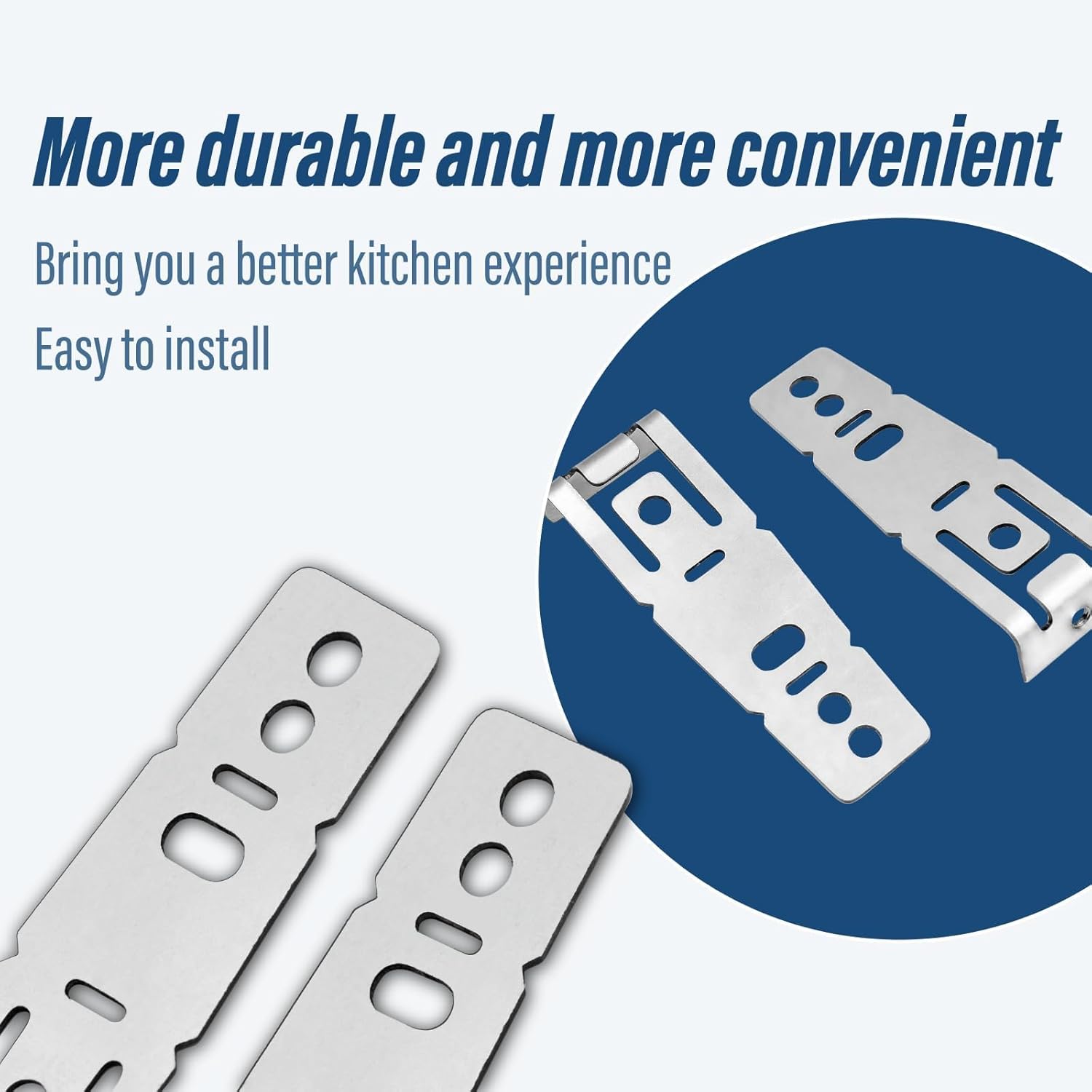

| Material | Steel, silver finish, rust-resistant treatment as described |

| Included components | WD01X21740 bracket x2, Screws x4 |

| Installation type | Under-countertop mounting; designed for quartz, engineered stone, and composite boards |

| Warranty | 6 months manufacturer warranty (as disclosed) |

The table highlights how the WD01X21740 functions as a fixing accessory rather than an appliance component. Its steel construction, compact dimensions, and included fasteners indicate straightforward mechanical mounting for compatible GE countertop models, and compatibility with common countertop materials suggests suitability for retrofit or replacement scenarios where reducing movement and aligning the dishwasher are priorities.

Stability and Vibration Control

A mounting bracket’s primary role is mechanical stabilization: by anchoring the dishwasher to the underside of the countertop, the bracket reduces lateral and torsional movement during pump and spray-arm cycles. The WD01X21740 clip-style brackets are manufactured from steel and designed to bend into pre-drilled shelf holes, which provides a direct load path from the appliance frame to the countertop substrate. Reduced movement lowers the risk of door misalignment, rattling, and intermittent contact between the appliance and adjacent cabinetry. Stability also moderates the transmission of vibrational energy into the countertop and surrounding fixtures, which can cut subjective noise in sensitive open-plan kitchens and preserve the integrity of seals and hose connections over time.

Effect on Spray Coverage and Cleaning Performance

Mechanical stabilizers do not change internal pump flow or spray-arm design, but improved alignment can support the optimal geometry of spray arms relative to dishes. When the dishwasher cabinet is securely anchored and level, spray patterns are more likely to clear intended target zones without being disrupted by device sway. Reduced movement helps maintain consistent clearances between spray arms and racks, decreasing the chance that large items or shifted racks will intermittently block jets. For households that rely on consistent cleaning on repeat cycles, a bracket that limits motion contributes to predictable spray coverage and fewer cycle-to-cycle variances in soil removal.

Noise Reduction and Open-Kitchen Suitability

Noise from countertop dishwashers commonly includes motor hum, pump chatter, and structure-borne vibration. A robust mounting clip converts free body movement into a constrained support, limiting resonant coupling between the dishwasher chassis and countertop. The steel WD01X21740 bracket, when correctly engaged and torqued with the supplied screws, reduces low-frequency rattles and high-frequency buzz that arise from loose fittings. While the bracket does not provide an acoustic rating, reducing structure-borne energy transmission improves subjective quietness in open kitchens where even small vibration-induced sounds can be noticeable.

Compatibility and Fit

Compatibility is a critical buyer consideration because mounting points, door geometry, and countertop edge thickness vary by model. The WD01X21740 is specified as a direct replacement for several OEM part numbers and lists compatibility with multiple GE countertop dishwasher SKUs. Fit depends on matching pre-drilled shelf-hole spacing and countertop overhang; the bracket’s shape and 4.33 x 4.13 inch footprint are intended to align with common mounting patterns for the referenced models. Selecting the correct bracket requires verifying model numbers, counter substrate thickness, and that the pre-drilled holes exist or can be produced without compromising the countertop. Mismatched brackets can lead to improper clamp engagement, which negates the stability benefits and can introduce stress concentrations at fastener points.

Model Fit and Pre-Drilled Hole Alignment

The WD01X21740 is designed to insert into pre-drilled shelf holes and be bent into place to secure the dishwasher frame. Accurate alignment of those holes is essential; hole spacing that deviates from the OEM pattern may require alternative hardware or re-drilling, which involves assessing the countertop material and backing structure. The bracket’s compatibility list includes common GE countertop models, which helps buyers cross-reference part numbers. For installations where holes are absent, using the bracket may necessitate collaboration with a countertop fabricator or installer capable of reinforcing the substrate while preserving surface integrity.

Countertop Materials and Load Distribution

Countertop composition—quartz, engineered stone, or composite board—affects how loads from the dishwasher are distributed and how fastening forces are absorbed. The WD01X21740’s steel clip transfers clamping force into the countertop through localized contact points; for brittle or layered stone, correct placement and torque control are important to avoid surface cracking or delamination. The bracket’s design and supplied screws are intended for typical countertop thicknesses associated with the compatible dishwasher models, but the installer should confirm that the countertop and any underlying cabinetry can bear the concentrated loads for operational cycles and that sealing or backing measures prevent moisture ingress at fastener sites.

Materials, Corrosion Resistance, and Durability

Material selection determines longevity in a humid kitchen environment. The WD01X21740 is specified as steel with a silver finish and is described as rust-resistant. Steel offers high tensile strength for load-bearing clips and repeated flexure during installation; a corrosion-resistant coating extends service life in the presence of steam and ambient moisture. Design aspects to consider include bend points where the clip is intentionally deformed during installation—those areas can become fatigue points if over-bent—and screw contact zones where galvanic interaction could accelerate corrosion if dissimilar metals are present. Long-term reliability depends on proper installation torque, environmental exposure, and periodic inspection for corrosion or loosening.

Steel Construction and Rust Resistance

Steel brackets balance strength and cost-effectiveness, and protective coatings mitigate oxidization in kitchen environments. The WD01X21740’s silver finish likely indicates zinc or similar plating that inhibits rust. Protective films and plating slow surface corrosion but do not make components impervious; edge cuts and deformation during installation can expose bare steel. Where equipment operates near steam or detergent aerosols, coated steel should be inspected periodically. For installations in coastal or high-humidity areas, additional corrosion protection or stainless-steel hardware may be advised to minimize long-term degradation and preserve clamping integrity.

Expected Service Life and Wear Points

Clips and brackets typically outlast many removable appliance components when installed correctly, but they are subject to wear at bend locations, screw holes, and areas of repeated mechanical loading. The WD01X21740 is intended as a replacement part and carries a short manufacturer warranty, which suggests typical service-life expectations for a small metal fastener assembly rather than a lifetime component. Inspectable wear points include any deformed bend tags, thread-stripped screw holes, and coating abrasion. If brackets are repeatedly removed and re-bent, fatigue accumulation may shorten functional life compared to a one-time secure installation.

Installation, Access, and Maintenance Considerations

Ease of installation influences buyer decisions in retrofit situations. The WD01X21740 package includes two brackets and four screws and is described as installable with a screwdriver and needle-nose pliers, inserting into pre-drilled holes and bending to secure. While the mechanical steps are straightforward, considerations include verifying compatibility with the appliance model, ensuring the countertop void or substrate can accept fasteners, and maintaining access to serviceable components like filters and hoses. A bracket that interferes with access panels or filter compartments can complicate routine maintenance, so placement that secures the appliance while preserving removable access panels is important for ongoing filter cleaning and hose inspection.

Installation Steps and Required Tools

Installation involves aligning the bracket with the appliance and countertop, inserting clip tabs into pre-drilled holes, bending tabs to lock the bracket to the shelf, positioning the dishwasher, and fastening screws through the round holes to the cabinet. Tools typically required are a screwdriver and pliers as noted; torque control on screws is recommended to avoid over-tightening that could stress countertop materials. The included screws are intended to match the bracket design, but in some retrofit cases alternate fasteners may be necessary to match substrate thickness. Verifying that the door closes and latches correctly after fastening completes the mechanical checks.

Maintenance, Inspection, and Access to Filters

A mounted dishwasher still requires routine maintenance such as filter cleaning, drain-line inspection, and occasional hose checks. Bracket placement should not obstruct removable access panels or the lower front panel used to reach filters and drain pumps. If the bracket overlaps service access, removal or repositioning may be necessary during maintenance—this highlights the trade-off between maximum stability and serviceability. Visual inspection of the bracket and screws every few months can detect loosening or corrosion early; tightened fasteners preserve vibration damping and reduce the potential for noise or alignment issues.

Impact on Performance: Noise, Drying, and Efficiency Expectations

A mechanical mounting bracket does not alter internal drying methods, water consumption, or rated energy performance, but it influences variables that affect perceived performance. By stabilizing the appliance, the WD01X21740 helps maintain consistent spray-arm geometry and reduces vibration that can affect door seals and detergent distribution. These indirect effects can translate into fewer cycle anomalies that cause residual moisture pockets or spotty rinse results. Noise reduction through vibration damping is the most direct performance impact; energy and water efficiency remain tied to the dishwasher’s pump, heater, and cycle designs and will be unaffected by mounting hardware beyond improved mechanical alignment.

Influence on Drying and Moisture Control

Drying systems—whether passive venting, condensation, or active heating—rely on consistent internal airflow and proper seal alignment to function predictably. A bracket that keeps the dishwasher square and minimizes door wobble helps maintain consistent gasket compression and door sealing, which can in turn stabilize internal humidity patterns during the drying phase. While the bracket does not add heat or change cycle logic, improved sealing reduces moisture ingress or egress that might otherwise affect condensation-based drying effectiveness or leave spots on glassware caused by inconsistent rinse coverage.

Energy and Water Efficiency Expectations

Energy and water usage are determined by the dishwasher’s engineered cycles, heater performance, and pump efficiency; mounting hardware does not directly affect those ratings. Nevertheless, a secure mounting that prevents movement-induced leaks or misalignment of spray arms reduces the risk of repetitive re-washes or manual pre-rinses—operational behaviors that increase net household water and energy use. Buyers should therefore treat the bracket as a reliability and stability investment that supports the dishwasher’s intended efficiency baseline rather than as a means to change the appliance’s certified consumption values.

Pros & Cons

Pros

- Solid, OEM-compatible replacement: The WD01X21740 matches multiple GE part numbers and ship-compatible model lists, simplifying part selection for known models. This reduces the risk of order errors for a retrofit or repair scenario.

- Steel construction with rust-resistant finish: Steel provides structural strength to resist movement during cycles, while plating or coating delays corrosion in humid kitchen environments when properly installed.

- Compact footprint and included hardware: The 4.33 x 4.13 inch clips and supplied screws are sized for direct engagement with most pre-drilled countertop hole patterns noted in compatibility lists, streamlining installation.

- Reduces vibration-related noise and door movement: Customer feedback patterns indicate fewer rattles and improved door alignment when brackets are used, which helps in open-plan kitchens where audible vibration is a concern.

- Compatible with hard countertops: Designed for use with quartz, engineered stone, and composite counters, the bracket supports common countertop installations without specialized anchors when holes exist.

- Simple mechanical installation: Installation requires basic hand tools (screwdriver and pliers) and avoids complex hardware or power tools for standard retrofit situations.

Cons

- Not a universal fit: The bracket depends on OEM-style pre-drilled holes and listed model compatibility; installations that do not match these patterns may require alternative hardware or countertop modification.

- Limited warranty and service life expectations: A short six-month manufacturer warranty signals typical small-part coverage; repeated removals or excessive bending during installation can contribute to early wear or fatigue.

- Potential for localized countertop stress: Incorrect torque or placement on brittle or thin stone can concentrate loads and risk surface damage; professional assessment may be required for some countertops.

- No direct acoustic or efficiency rating: The bracket itself carries no certified noise reduction or energy-impact ratings; its benefits are indirect and contingent on proper installation and appliance condition.

Final Verdict: Who This Dishwasher Is Best For (and Who Should Skip It)

The WD01X21740 bracket is appropriate for homeowners and service technicians seeking an OEM-compatible mounting solution for compatible GE countertop dishwasher models. It suits compact kitchens where vibration control and door alignment matter—particularly in open-plan living spaces where structure-borne noise is noticeable. The steel, rust-resistant construction and included fasteners make it a practical replacement part when pre-drilled holes and matching model numbers are present. It supports proper spray-arm geometry and maintains gasket compression, helping appliances deliver consistent cleaning cycles as designed.

This bracket is not recommended for installations lacking compatible pre-drilled mounting points, for countertops with questionable structural backing, or for users seeking an acoustic-certified solution. For coastal or high-humidity environments where maximum corrosion resistance is required, selecting stainless or specialist fasteners may be preferable. Overall, the WD01X21740 functions as a targeted stability and alignment accessory that helps preserve dishwasher performance when matched to the correct appliance models and countertop substrates.

Frequently Asked Questions (FAQs)

What does the WD01X21740 bracket do for a countertop dishwasher?

The WD01X21740 bracket anchors a countertop dishwasher to the underside of a countertop to limit lateral and torsional movement. By stabilizing the cabinet, the bracket reduces vibration-induced rattles and helps maintain spray-arm geometry and door alignment, which supports predictable cleaning performance and reduces the likelihood of cycle irregularities caused by excessive motion.

Is the WD01X21740 bracket compatible with all countertop dishwashers?

The WD01X21740 is specified as a direct replacement for particular GE part numbers and models. Compatibility requires matching the dishwasher model and pre-drilled shelf-hole pattern; installations without the OEM-style holes or with different chassis geometries may need alternate hardware or countertop modification to ensure a secure fit.

Can the bracket reduce dishwasher noise in open kitchens?

While the bracket does not carry an acoustic rating, properly securing the dishwasher to the countertop reduces structure-borne vibration and associated rattles. This damping of mechanical motion can lower subjective noise levels in open kitchens, especially where small vibrational sounds would otherwise be amplified by countertop resonances.

Will installing the bracket affect dishwasher drying or energy use?

The bracket does not modify internal drying methods or certified energy and water consumption. However, it can help maintain proper gasket compression and spray-arm placement, which supports consistent drying outcomes and reduces the need for repeated cycles or manual rinses—operational behaviors that can indirectly influence household energy and water use.

What tools and time are typically needed to install these brackets?

Installation commonly requires basic hand tools such as a screwdriver and needle-nose pliers to insert and bend the clip tabs into pre-drilled holes, then fasten the supplied screws. Time depends on access and pre-drilled hole availability but is generally brief for retrofit scenarios where compatible holes are present; complex countertops or absent holes may require additional preparation.

Are there maintenance considerations after installing the bracket?

Periodic inspection of the bracket and screws is advisable to ensure fasteners remain tight and coatings are intact. If the bracket interferes with access to filters or service panels, it may need temporary removal for maintenance. Watch for corrosion at edges or bend points, especially in high-humidity environments, and replace the bracket if fatigue or coating failure is evident.

Is special hardware needed for granite or quartz countertops?

The WD01X21740 is described for use with quartz, engineered stone, and composite countertops, but installation should account for substrate fragility and backing. For brittle stone or thin slabs, reinforcing the attachment area or using substrate-specific anchors may be necessary to distribute load and prevent surface damage.

How long is the warranty and what does it cover?

The bracket is offered with a six-month manufacturer warranty as disclosed. This typically covers defects in materials and workmanship for the replacement part, but buyers should review warranty terms for specifics about coverage, exclusions, and remedies in the event of early failure.