Secure Dishwasher Mounting for Quieter, Stable Kitchens Today

Why mounting hardware matters for dishwasher selection

Choosing a dishwasher involves more than cycle counts and interior layout; mounting details influence real-world performance and longevity. Stability of a built-in unit affects vibration transfer to cabinets and countertops, seal compression at the door perimeter, and alignment of inlet/drain connections. Households with open-plan kitchens, frequent use, or heavy loads benefit from secure anchoring that limits movement under full wash loads and during spin cycles. For stone countertops—granite, quartz, and similar materials—an under-counter mounting solution that avoids side-cabinet damage and can be fitted before or after countertop installation simplifies integration. The material and fastening approach determine resistance to corrosion in humid environments near the dishwasher chassis and help preserve surrounding cabinetry. For buyers prioritizing reduced noise, consistent cleaning results, and long-term reliability, mounting hardware should be evaluated alongside internal wash systems and energy ratings when selecting a built-in dishwasher.

Quick Overview

| Feature | Details |

|---|---|

| Product type | Under-counter dishwasher mounting bracket (installation accessory) |

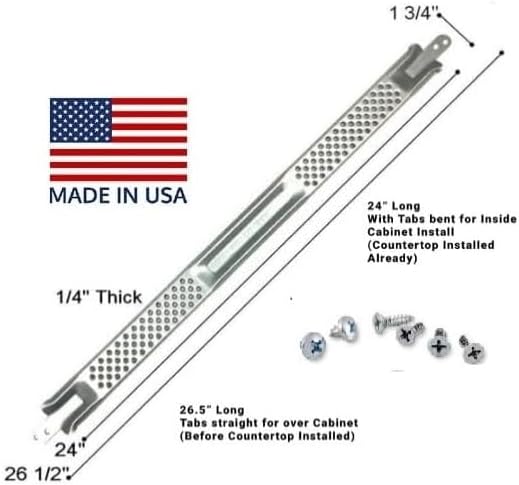

| Material | 22 gauge galvanized steel; Made in USA |

| Compatibility | Designed for most common 24″ built-in dishwashers; lists compatible part numbers W10426979, 231179, AH3632890, EA3632890, PS3632890 |

| Mounting hardware | Mounting screws included; installs prior to or after countertop installation |

| Installation suitability | Works with granite, quartz and other countertop materials; avoids side-cabinet anchoring |

| Noise rating | Not applicable (accessory) |

| Energy/water certifications | Not applicable (accessory) |

| Manufacturer / ASIN | EZVentures; ASIN: B097BTWGFQ |

| Ranking & popularity | Best Sellers Rank listed in Industrial & Scientific and Hardware Brackets categories |

This bracket is positioned as a practical mounting accessory for 24-inch built-in dishwashers in kitchens with stone or solid-surface countertops. The two-column summary highlights compatibility, material, and installation flexibility, which translate to a solution for installers and homeowners who want a standardized under-counter anchoring method without relying on side-cabinet fasteners that can damage expensive cabinetry.

Cleaning performance and spray coverage considerations

Mounting hardware does not directly change spray arm design or heater performance, but stable anchoring influences cleaning outcomes by preserving door seal integrity and preventing misalignment of the chassis with water inlet and drain plumbing. Excessive chassis movement can lead to hairline shifts that alter spray coverage geometry or allow minor leaks that interfere with drying cycles. A robust bracket constructed from galvanized steel reduces chassis wobble and maintains consistent clearance between the dishwasher and adjacent cabinetry under load. For households that run heavy or frequent cycles, ensuring the appliance remains plumb and securely anchored prevents progressive seal wear and maintains designed spray patterns for thorough coverage across upper and lower racks.

How bracket stability affects spray distribution

Spray arms and nozzles are engineered with precise clearances so water jets reach tines and dishes as intended. If the dishwasher shifts during a cycle, spray arms can experience altered flow paths or contact with racks, leading to localized underperformance. A solid under-counter bracket minimizes lateral movement and rotational play by securing the top apron to the countertop underside, preserving the engineered spray geometry. This restraint is particularly relevant when multi-rack loading concentrates weight unevenly, as consistent alignment supports even wash coverage and reduces the chance of repeated soil spots on plates or glassware.

Seal integrity, leak prevention, and long-term cleaning consistency

Door seal compression is essential for both effective washing and drying. Uneven or intermittent compression caused by a loosely mounted appliance can allow steam or wash water to escape, lowering cycle efficiency and potentially disturbing detergent distribution. A mounting bracket that holds the unit squarely under the countertop helps maintain uniform gasket contact across the door perimeter. Over time, consistent sealing reduces the risk of margin leaks that could affect cabinetry and supports reliable cleaning cycles by maintaining the intended internal environment for detergent action and rinse performance.

Capacity, rack design, and place settings implications

Bracket selection does not change internal capacity or rack configuration, but installation geometry impacts usable clearance and the ability to fully extend racks during loading. An under-counter bracket that sits flush with the countertop underside preserves toe-kick and cabinet alignment, ensuring drawers and adjacent cabinetry operate without interference. For kitchens where dishwashers are loaded with larger cookware or tall stemware, proper anchoring prevents sag or tilt that would restrict upper-rack height adjustments. Buyers comparing place settings should verify that the chosen bracket accommodates the specific 24-inch chassis model to avoid any impact on rack travel or the ability to use adjustable tines and fold-down features as intended by the manufacturer.

Preserving rack travel and adjustable features

Rack ergonomics—such as adjustable upper rack height, fold-down tines, and third-rack options—depend on consistent chassis position relative to the cabinet face. If a unit is not secured properly, repeated use can result in slight shifts that impede smooth rack extension or lead to rubbing against the door or cabinet. A bracket that secures the top of the dishwasher to the countertop prevents progressive shifts and keeps rack mechanisms aligned. This matters when users need to accommodate large pots or tall glasses, and when the dishwasher’s interior flexibility contributes to overall capacity utilization.

Installation clearances and compatibility with accessories

Some dishwashers include anti-tip features, leveling legs, or installation extenders that require a predictable mounting plane. Under-counter brackets designed for shallow profiles preserve the necessary clearance for leveling feet and allow installers to reach adjustment points without removing the countertop. Compatibility with common 24-inch built-in models reduces the chance of unexpected interference with rail-mounted racks, detergent dispensers, or third-rack inserts. Confirming model compatibility and following manufacturer guidelines ensures full access to capacity-related features and prevents unintended limitations on place setting flexibility.

Noise levels and suitability for open-plan kitchens

Noise ratings are a key consideration for open-plan living spaces. While a mounting bracket does not emit noise, it contributes to perceived sound levels by damping vibration pathways between the dishwasher and surrounding structure. Galvanized steel brackets that secure the appliance to a stable, non-resonant surface reduce structure-borne noise transfer. Minimizing chassis movement prevents rattles and intermittent sounds associated with loose mounting points. For households sensitive to conversational speech or media playback near the kitchen, anchoring approaches that isolate the dishwasher from cabinetry resonance can make a measurable difference to the subjective quietness of operation even when the motor and pump noise levels remain the same.

Vibration isolation versus rigid anchoring trade-offs

A rigid bracket reduces lateral movement but must be installed so it does not create a hard vibration path into lightweight cabinetry. Combining a sturdy under-counter bracket with anti-vibration pads or recommended installation practices limits both movement and resonance. Galvanized steel provides durable support, but installers should consider whether the bracket contacts solid stone tops or adhesives that could transmit noise differently. Careful placement and the addition of non-metallic buffering where appropriate maintain anchoring benefits while lowering the risk of amplified structure-borne noise in open living areas.

Long-term noise implications for heavily used kitchens

Repeated use amplifies the visibility of minor installation-related noises; small fastener loosening or slight misalignment can produce intermittent rattles that become noticeable over time. A bracket that uses included mounting screws and resists corrosion preserves tight connections and reduces the likelihood of future noise issues. For households that run multiple cycles daily or host frequent gatherings in adjoining spaces, investing in a mounting method that maintains a secure interface supports sustained low-noise operation and helps the appliance meet user expectations for quiet performance.

Drying systems and moisture control considerations

Drying performance in dishwashers depends on internal design—condensation drying, fan-assisted systems, or heated elements—but installation affects moisture pathways external to the machine. A properly mounted dishwasher maintains drain line routing and prevents low spots that can trap water, which otherwise may contribute to lingering moisture or odor near the base. Ensuring the unit sits squarely under the countertop also maintains correct slope for the drain and prevents pooling at the gasket interface. For homes that rely on condensation drying, preserving door alignment and seal compression is especially important to ensure steam exits and condenses on the interior surfaces as designed, rather than escaping and increasing ambient humidity.

How installation affects drainage and condensation patterns

Drain and overflow performance relies on consistent plumbing connections and correct appliance pitch. An under-counter bracket that secures the top of the unit helps keep the chassis level, preserving the intended slope of internal components and drain lines. If a dishwasher leans forward or sideways, water can collect in low points, impairing both draining and drying cycles, and increasing the likelihood of residual moisture on dishes or within the sump area. Maintaining correct positioning supports the manufacturer’s drainage geometry and minimizes unintended moisture retention.

Moisture control at the cabinet interface

When steam exits through small gaps due to imperfect door sealing, it may condensate on cabinetry or the underside of a countertop. A bracket that holds the dishwasher in consistent contact with the countertop underside helps maintain even gasket pressure and reduces peripheral steam escape. For kitchens with sensitive cabinetry materials or exposed wood undersides of countertops, limited steam migration reduces the risk of moisture-related finish issues. Properly installed mounting hardware aids the drying subsystem’s ability to confine moisture internally until it is dispersed through venting or condensation pathways designed by the dishwasher manufacturer.

Energy and water efficiency expectations, maintenance, and durability

Bracket choice does not alter a dishwasher’s rated energy or water consumption, but correct installation supports consistent operation that allows the machine to meet its certified efficiency. Misalignment that produces leaks or impairs cycle completion can cause repeat runs or manual drying that increase water and energy use. The bracket’s galvanized material contributes corrosion resistance in humid environments, aiding long-term durability of the mounting point. Maintenance obligations remain appliance-centric—regular filter cleaning and spray-arm inspection—but a well-secured chassis reduces access issues and limits stress on hoses and electrical connections, simplifying routine service and extending expected appliance reliability.

Role in preventive maintenance and filter access

Routine filter cleaning and sump access are necessary for maintaining wash performance and preventing odors. A mounting bracket that permits straightforward removal or repositioning of the dishwasher during service helps technicians reach filters, pumps, and hoses without forcing attachments or risking cabinet damage. The EZVentures bracket can be installed before or after countertop placement, allowing service access strategies to be planned around cabinetry and facilitating periodic maintenance without extensive disassembly.

Durability of materials and long-term reliability

Galvanized steel resists surface corrosion better than plain steel in damp kitchen environments, maintaining fastener integrity and mounting geometry over time. A 22 gauge thickness balances structural support with low profile fit under countertops. Consistency of material and inclusion of mounting screws reduce variability during installation, lessening the chance of early loosening. For homeowners focused on long-term reliability, choosing corrosion-resistant mounting hardware reduces the probability of follow-up adjustments or bracket replacement, contributing indirectly to sustained dishwasher performance and reduced service interventions.

Pros & Cons

Pros

- Compatible with common 24-inch built-in dishwashers: The bracket lists multiple compatible part numbers and brand fits, supporting use across widely sold models and simplifying installer selection.

- Made from 22-gauge galvanized steel: Galvanization provides corrosion resistance appropriate for humid appliance locations, offering a durable mounting surface that resists surface rust.

- Installs before or after countertop placement: Flexibility in installation timing benefits renovation schedules and avoids the need to have the appliance present at the job site.

- Mounting screws included: Inclusion of hardware reduces the need to source fasteners separately and standardizes the attachment approach for installers.

- Designed for stone countertops: Under-counter attachment avoids side-cabinet anchoring that could damage expensive cabinetry or require return visits by countertop installers.

- Reduces chassis movement and potential noise transfer: A secure mounting point helps maintain door seal compression and minimizes vibration-related rattles in adjacent cabinetry.

- Simplifies service access planning: A predictable under-counter mounting plane helps technicians remove or reposition the appliance for filter and sump maintenance without disturbing cabinets.

- Manufactured in the USA: Domestic production can simplify supply chain logistics and aligns with buyers preferring local manufacturing sources.

Cons

- Not a substitute for model-specific installation instructions: While compatible with many 24-inch units, installers must confirm fit with the exact dishwasher model to avoid interference with trim or leveling parts.

- Does not address motor or pump noise: The bracket reduces structure-borne noise transfer but does not change intrinsic sound levels produced by the appliance’s mechanical components.

- Gauge and design limit heavy-duty industrial use: At 22 gauge thickness, the bracket is intended for residential applications and may not be optimized for non-standard commercial chassis loads.

- No manufacturer-stated warranty details provided: The product listing does not specify warranty terms, requiring buyers to verify protection and support options directly with the manufacturer.

Final Verdict: Who This Dishwasher Is Best For (and Who Should Skip It)

This mounting bracket is appropriate for homeowners, contractors, and countertop installers working with 24-inch built-in dishwashers and solid-surface countertops who need a low-profile, corrosion-resistant method to secure an appliance under stone or composite tops. It suits busy households prioritizing noise reduction and long-term seal integrity without altering dishwasher internal systems. Installers who value the ability to complete anchoring before or after countertop installation will find the included hardware and galvanized construction advantageous for avoiding cabinet-side anchors that can damage expensive millwork.

This accessory is not intended for buyers seeking to change wash performance, lower motor noise at the source, or increase internal capacity; such outcomes require selecting a different dishwasher model. It is also less suitable for atypical commercial installations or for chassis sizes outside the common 24-inch built-in range. Before purchase, verifying exact model compatibility and clarifying warranty or support expectations with the manufacturer is recommended to ensure the bracket meets installation and durability needs compared with other mounting solutions available in 2026.

Frequently Asked Questions (FAQs)

How does a mounting bracket affect dishwasher noise levels?

A mounting bracket reduces structure-borne noise by limiting chassis movement and preventing loose contact points that can rattle. While it does not change motor or pump noise, improved anchoring reduces vibration transfer into cabinetry and countertops, which often lowers perceived sound in open-plan kitchens. Proper installation and optional vibration padding further manage resonance between the bracket, countertop, and cabinet materials.

Will this bracket work with all 24-inch built-in dishwashers?

The bracket is designed to accommodate most common 24-inch built-in models and lists compatible part numbers and brands. However, dishwasher trim, leveling feet, or model-specific mounting points can vary. Verifying compatibility with the exact chassis dimensions and installation points for the targeted model before purchase is recommended to avoid interference with racks, controls, or access panels.

Can the bracket be installed before the countertop is set?

Yes, the design allows for installation prior to or after countertop placement. This flexibility supports renovation workflows where the appliance may not be on site during countertop installation. Correct alignment and fastener selection remain important to preserve the intended mounting plane and to ensure seal compression and drain routing remain consistent once the dishwasher is installed.

Does the bracket improve dishwasher cleaning performance?

Indirectly. The bracket helps maintain chassis alignment and door seal integrity, which supports the dishwasher’s designed spray geometry and prevents wash water escape. While internal cleaning systems—spray arms, pumps, and filtration—determine primary cleaning performance, a stable mounting reduces variables that can degrade long-term wash consistency, such as gasket wear or misaligned spray coverage.

Is galvanized steel a good material for kitchen appliance brackets?

Galvanized steel offers corrosion resistance suitable for humid kitchen environments and provides structural support for residential dishwasher installations. The zinc coating helps protect against surface rust where moisture is present. For long-term durability, ensuring the bracket does not have persistent contact with highly acidic cleaners or stray salts will preserve the protective galvanic layer.

Does installing this bracket change warranty or service access?

The bracket itself does not alter the dishwasher’s manufacturer warranty, but improper installation could affect serviceability. A properly installed under-counter bracket that allows the dishwasher to be removed or repositioned without cabinet damage can simplify routine maintenance like filter cleaning and pump access. Consumers should consult both the dishwasher’s installation instructions and the bracket manufacturer’s guidance to maintain warranty compliance.