Secure Dishwasher Installation for Quiet, Stable Performance

Why Dishwasher Selection and Mounting Matter

Selecting the right dishwasher is more than choosing cycles and finish; mounting hardware and installation details directly influence cleaning performance, noise transmission, and long-term reliability. Household size, kitchen layout, and usage frequency dictate expectations for capacity and endurance, while countertop material and clearance shape installation choices. Proper anchoring affects vibration transfer and alignment, which can change spray arm coverage, gasket seating, and drain performance. Noise-sensitive households and open-plan kitchens benefit when mounting reduces rattles and movement. Efficiency expectations are affected indirectly as stable alignment helps maintain consistent spray patterns and proper drain function. For households prioritizing quiet operation, minimal maintenance, and compatibility with stone or engineered countertops, mounting brackets designed for pre- or post-countertop installation can be critical to achieving the intended dishwasher performance without invasive modifications.

Quick Overview

| Feature | Details |

|---|---|

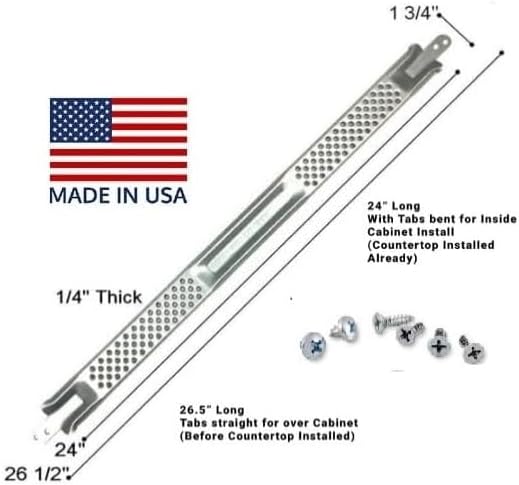

| Product type | Under-counter dishwasher mounting bracket |

| Compatibility | Designed for common 24″ built-in dishwashers (many Whirlpool-family models and similar) |

| Material & finish | 22 gauge galvanized steel, powder coated, silver finish |

| Installation | Can be installed before or after countertop installation; mounting screws included |

| Countertop types | Compatible with granite, quartz, and other solid surfaces |

| Included hardware | Mounting screws included |

| Country of origin | Made in USA |

| Unit count | 1.0 Count |

This bracket translates into practical household suitability by providing a standardized, corrosion-resistant anchoring point for most 24″ built-in dishwashers. It is intended to simplify installation when working with stone or engineered countertops where standard toe-kick anchoring is impractical. Inclusion of mounting screws and the ability to install the bracket before a dishwasher is onsite reduces coordination between countertop and appliance installation. The galvanized steel construction aims to balance strength and corrosion resistance for long-term stability under the sink and cabinetry environment.

Cleaning Performance and Spray Coverage: Mounting Impacts on Wash Results

A dishwasher mounting bracket does not change the internal wash mechanics but influences the physical alignment and stability that underlie consistent spray coverage and drainage performance. A securely anchored chassis reduces lateral movement during high-torque spray cycles and during pump operation; this stability helps maintain intended spray arm trajectories and consistent nozzle orientation. If a unit shifts or tilts due to poor anchoring, spray arms can lose range of motion or spray angles can partially miss dish surfaces, reducing cleaning efficiency. Proper mounting also helps preserve gasket compression and door seal alignment, reducing the potential for water escape and ensuring programmed cycles run as designed. The FITALL E-Z bracket’s universal compatibility and solid steel construction are designed to minimize movement that can indirectly affect cleaning outcomes.

Spray arm range, coverage, and alignment considerations

Spray arms rely on consistent rotational clearance and unobstructed flow paths to deliver water and detergent evenly across racks. A mounting bracket that holds the dishwasher level and prevents fore-aft or lateral shifts maintains the designed clearances between spray arms and inner walls, utensil racks, and lower-loading items. When a dishwasher is properly fastened, spray arm RPM and pressure distribution remain within manufacturer tolerances, which supports even soil removal across cycles. The FITALL bracket’s adjustability and compatibility with common 24″ units are intended to allow installers to position the appliance so spray arm sweep is not impeded by cabinetry or misaligned cutouts.

Filtration, drainage, and moisture control influences

Stable installation also supports consistent drainage geometry and filter seating. When a dishwasher tilts forward or backward, the sump and drain port can sit at suboptimal angles relative to the waste line, increasing the chance of standing water or incomplete draining that affects subsequent cycles and drying performance. Properly anchored units help maintain intended water paths and keep the filter basket properly compressed to catch large debris, which in turn reduces microfilm, redeposition, and odors. The bracket’s secure attachment points are designed to reduce misalignment risks that can change inlet and outlet orientations over time.

Capacity, Rack Design, and Place Settings: Impact of Installation Fit

Physical capacity and rack configuration are fixed by the dishwasher model, but cabinet alignment and installation height affect usable space and loading ergonomics. A correctly positioned unit with the right mounting bracket prevents toe-kick interference and allows racks to fully extend without rubbing on cabinetry. This bracket accommodates standard 24″ built-in appliances, which in most models support 12–16 place settings; ensuring full rack travel preserves the intended loading patterns and access to adjustable tines, stemware shelves, or third rack options. Countertop clearance and the bracket’s under-counter fastening method can influence how closely the unit fits to adjacent cabinetry—important for optimizing loading convenience and preventing repeated contact that could damage racks or coatings.

Rack extension, adjustability, and third-rack considerations

Rack systems depend on unobstructed glide paths and stable hinge points. When a dishwasher is flush-mounted with correct clearance, upper and lower racks can extend fully without binding, allowing users to position large pots and delicate glassware as intended. Brackets that allow for pre-installation under solid surfaces permit installers to size the opening precisely so adjustable upper rack positions remain usable. For units with a third rack, full support relies on the unit being aligned horizontally; misalignment can create uneven wear on roller tracks and impair smooth travel, reducing effective capacity and convenience.

Place settings, load patterns, and ergonomic access

Proper mounting affects how easily diners load and unload dishes, which can influence practical capacity utilization. A unit that sits too deep or is tilted can change the perceived space within each rack pocket, causing items to be repositioned and potentially blocking spray paths. The FITALL E-Z bracket’s compatibility with typical 24″ units aims to ensure that place settings count and rack geometry remain functionally accessible. This bracket also accommodates installations where countertop overhangs might otherwise limit top rack entry, preserving manufacturer-rated place settings and loading ergonomics.

Noise Levels and Suitability for Open Kitchens

Noise transmission from a dishwasher is influenced by mechanical components, insulation, and how vibration couples into surrounding cabinetry and countertops. A mounting bracket that provides rigid, well-distributed attachment points reduces cabinet rattles and resonant amplification of pump and motor noise. When a dishwasher is isolated poorly, small gaps and loose fasteners can convert internal vibrations into louder, broadband noise that is noticeable in open-plan living areas. The FITALL E-Z bracket’s 22 gauge galvanized steel construction and secure screw mounting are intended to create a firm interface between the appliance and countertop substrate, reducing movement that commonly raises perceived noise levels. For noise-sensitive homes, ensuring tight, strain-free fastening is as important as the dishwasher’s internal sound rating.

Decibel ratings context and perceived loudness in open spaces

Decibel ratings provide an objective baseline, but perceived loudness in an open kitchen depends on how structure-borne vibration couples into cabinetry and counters. A well-anchored unit with minimal panel flex will limit low-frequency vibrations that propagate into building structure, which are often the most intrusive in adjacent living spaces. Conversely, even a dishwasher with a modest dB rating can sound louder if the mounting allows panel resonance. This bracket’s design to fit under stone and engineered counters aims to stabilize the appliance-to-countertop interface, helping maintain the sound level experienced in open-concept layouts closer to manufacturer expectations.

Anti-vibration considerations and installer best practices

Materials and fastening technique influence vibration isolation. While the bracket itself is rigid, installers can incorporate rubber washers or isolation pads at screw interfaces to further reduce transmission into cabinetry. Ensuring the bracket is fastened to stable substrate and that the dishwasher feet are adjusted to bear weight evenly prevents rocking that can intensify noise. The FITALL E-Z bracket includes mounting screws and supports pre- or post-countertop installation, providing flexibility to position the appliance correctly before final fastening, which reduces the likelihood of stress-induced noise later.

Energy, Water Efficiency Expectations and Maintenance Requirements

A mounting bracket does not alter a dishwasher’s rated energy or water consumption, but it affects conditions that help those ratings be realized in real-world operation. Proper leveling and secure anchoring support consistent spray coverage and drainage, which helps cycles clean effectively without requiring repeat runs. In solid-surface countertop installations, the ability to fasten the appliance without modifying the cabinet structure reduces the risk of misroute plumbing or kinked drain lines that can impair flow. Maintenance considerations include ensuring access to the filter basket and lower panel for debris removal; a bracket that allows full front-panel removal and toe-kick access simplifies routine cleaning and inspection, prolonging component life and helping maintain manufacturer-rated efficiency.

Certifications, expected water usage patterns, and cycle interactions

Dishwasher models carry energy and water efficiency certifications that assume proper installation and maintenance. A bracket that supports correct appliance siting helps maintain the geometry required for efficient rinse and drain cycles, which contributes to achieving published usage figures. Proper mounting also minimizes the potential for misalignment that can lead to trap priming issues or siphoning effects in certain drain configurations. While the bracket itself does not provide certification, it is a piece of the installation puzzle that helps ensure the dishwasher operates within designed parameters for efficiency.

Filter access, debris management, and preventative maintenance

Accessible filter baskets and unobstructed access to the sump area are essential for preventing clogs and maintaining spray pressure. A mounting method that requires extensive panel removal or restricts toe-kick access can make routine debris removal less likely, increasing long-term maintenance needs. The FITALL E-Z bracket’s under-counter mounting approach is intended to avoid obstructing normal service points, and the included hardware aims to streamline secure attachment without blocking inspection openings, supporting regular maintenance that preserves cleaning performance and water efficiency.

Durability, Material Choices, Compatibility, and Installation Trade-offs

Durability in mounting hardware depends on material selection, coating, and mechanical design. The FITALL E-Z bracket is made from 22 gauge galvanized steel with a powder-coated finish, combining substrate corrosion resistance with surface protection against nicks and moisture commonly found in under-cabinet spaces. Galvanized steel resists common forms of corrosion better than bare steel in moderately humid environments, while powder coating adds a barrier to electrolytic attack. The bracket’s universal fit claims and compatibility with numerous Whirlpool-family part numbers imply design tolerances intended to suit common frame geometries; however, compatibility is contingent on cabinet opening dimensions, countertop overhangs, and dishwasher toe-kick designs. Trade-offs include the bracket’s rigidity, which favors stability but may require shimming to accommodate out-of-plumb cabinetry.

Corrosion resistance, mechanical life, and finish durability

Galvanized coatings provide sacrificial protection that slows corrosion of the underlying steel, while powder coating enhances scratch and moisture resistance. In typical kitchen environments, these treatments extend functional life relative to uncoated steel, particularly when fastener points are sealed and installation avoids prolonged water exposure. Mechanical life also depends on gauge and design: 22 gauge offers structural support for anchoring but is thinner than heavier brackets used in commercial settings, which means careful screw placement and avoidance of over-torquing are advisable to prevent deformation over time.

Compatibility constraints, fitment checks, and installer considerations

Despite universal-fit marketing, real-world compatibility depends on precise measurements: cabinet face frame or frameless opening, countertop overhang, dishwasher height adjustment range, and presence of integrated toe-kicks or front-venting designs. The bracket is designed to be installed before or after countertop placement to accommodate stone surfaces, but installers should verify clearance for hose routing and vent locations. In some tight installations, additional modifications or alternative attachment points may be required. The included mounting screws simplify installation, but installers may need supplemental fasteners or isolation washers depending on cabinet substrate and vibration management preferences.

Pros & Cons

Pros

- Broad compatibility with 24″ built-in dishwashers: The bracket lists cross-compatible part numbers and common Whirlpool-family models, simplifying selection for many standard built-in units and reducing the need for custom fabrication in typical residential installations.

- Made in USA with galvanized steel construction: Manufacturing origin and 22 gauge galvanized steel construction indicate an emphasis on domestic production and corrosion-resistant materials suitable for wet cabinet environments.

- Powder-coated finish for surface protection: The powder coat provides additional protection against scratching and moisture exposure, extending cosmetic and functional lifespan where contact with cabinetry or tools can occur.

- Mounting screws included and pre/post countertop installation supported: Inclusion of hardware and the ability to fit the bracket before or after countertop installation support scheduling flexibility between countertop templating and appliance delivery.

- Aims to reduce vibration-related noise: The bracket’s rigid attachment points are intended to minimize appliance movement that can amplify motor and pump noise into surrounding cabinets and counters, aiding quieter operation in open kitchens.

- Simple design reduces installation complexity: A straightforward plate-style bracket with common screw fasteners simplifies anchoring compared with custom metalwork or retrofit anchoring solutions, which can reduce installation time and uncertainty for standard openings.

Cons

- Limited to 22 gauge thickness: While adequate for typical residential use, 22 gauge is thinner than some heavy-duty commercial brackets and may require careful installation to avoid deformation under misapplied torque or repeated stress.

- Universal-fit claims may need verification: Compatibility with many models hinges on cabinet and countertop geometry; some non-standard toe-kicks, integrated venting, or compact dishwasher models may not align without modification.

- Does not include isolation hardware by default: For installers prioritizing vibration decoupling, the package does not include rubber washers or pads, which may necessitate sourcing additional materials to reduce structure-borne noise further.

- Powder coating can be scratched during retrofit work: Field cutting or fitting in tight openings risks damaging the finish, which could reduce corrosion protection at exposed edges if not touched up properly.

Final Verdict: Who This Dishwasher Bracket Is Best For (and Who Should Skip It)

This bracket is best for homeowners, remodelers, and professional installers seeking a straightforward under-counter anchoring solution for standard 24″ built-in dishwashers, especially when working with stone or engineered countertops where traditional top-mount clips are impractical. The galvanized, powder-coated construction and included screws provide a practical balance of corrosion resistance and immediate usability for typical residential kitchens. It suits households prioritizing stable mounting to preserve spray arm coverage, minimize vibration-related noise, and maintain proper drain geometry without modifying countertops or cabinetry extensively.

It may not be the ideal choice for installations requiring heavy-duty reinforcement (commercial settings), non-standard dishwasher footprints, or integrated-panel models with unique toe-kick and venting arrangements. Installers who require built-in vibration isolation hardware or thicker-gauge structural support should consider supplementary isolation pads or alternative brackets. Overall, for 24″ residential built-ins where maintaining alignment, stability, and compatibility with stone countertops is essential, this bracket provides a pragmatic, domestically produced option that addresses common installation challenges while supporting dishwasher performance expectations.

Frequently Asked Questions (FAQs)

How does a mounting bracket affect dishwasher cleaning performance?

A mounting bracket itself does not change internal wash mechanics, but it stabilizes the appliance. Secure anchoring maintains level and alignment, ensuring spray arms have full sweep and the sump and drain remain at designed angles. This reduces risk of incomplete coverage, standing water, and repeated cycles. Proper installation helps preserve gasket seating and consistent nozzle trajectories, which supports the dishwasher’s intended cleaning performance.

Will this bracket fit my 24-inch built-in dishwasher?

The bracket is designed for broad compatibility with common 24″ built-in models and lists multiple Whirlpool-family part numbers as references. Fit depends on cabinet opening, toe-kick configuration, and countertop overhang. Measuring height, depth, and clearances for hose routing and venting is recommended to confirm compatibility before installation. Some non-standard models may require adjustments or alternate mounting strategies.

Can the bracket reduce dishwasher noise in open-plan kitchens?

A rigid, properly installed bracket can reduce structure-borne noise by limiting appliance movement and panel rattles. While it does not change the dishwasher’s inherent motor or pump noise rating, minimizing vibration transfer into cabinetry and countertops often lowers perceived loudness in adjacent living areas. For maximum benefit, installers can add isolation washers or pads where the bracket meets cabinetry.

Is the FITALL E-Z bracket corrosion resistant for under-cabinet environments?

The bracket is made from 22 gauge galvanized steel with a powder-coated finish, which offers a combination of sacrificial and surface protection against moisture-related corrosion typical in kitchen cabinets. While this treatment enhances durability, exposed scratched areas should be touched up to maintain long-term corrosion resistance, especially in humid environments or near the sink area.

Will installing the bracket affect dishwasher energy or water efficiency?

The bracket does not alter a dishwasher’s rated energy or water use. However, proper leveling and secure mounting help the appliance achieve its designed spray coverage and drainage, which supports real-world efficiency. Poor installation that allows tilting or obstructions can impair cleaning and drainage, sometimes leading to repeat cycles that increase water and energy use.

Are additional materials needed for vibration isolation during installation?

The bracket includes mounting screws but does not include dedicated isolation pads or rubber washers. For installations prioritizing noise control, adding rubber washers or isolation pads at fastener points can further reduce structure-borne vibration. Installers should evaluate cabinet substrate and consider supplemental hardware to meet specific acoustic requirements.

Can this bracket be installed before or after countertop installation?

The bracket is designed to accommodate both pre- and post-countertop installation workflows, which is useful when working with heavy stone or engineered surfaces. This flexibility helps coordinate countertop templating and appliance delivery without requiring the dishwasher to be on-site during fabrication or final cabinet work.

What maintenance considerations relate to using this bracket?

Maintenance primarily involves ensuring that the bracket and fasteners remain secure and that access to the dishwasher’s filter and lower panel is unimpeded. Periodic checks for loose screws, signs of finish wear, and proper dishwasher leveling are recommended. If the powder coating is scratched, touch-up coating will help preserve corrosion resistance over time.