Secure WD01X27759 Dishwasher Brackets for Fit & Stability

Why Mounting Brackets Matter for Dishwasher Performance

Selecting a dishwasher mounting bracket is a small decision with measurable effects on appliance performance, noise, and longevity. Proper mounting stabilizes a dishwasher body, maintains correct alignment of spray arms and drain lines, and reduces vibration transfer to cabinetry or countertops — factors that influence perceived cleaning performance and operational sound. Household size, kitchen layout, and usage frequency inform whether a robust bracket is required: busy families and open-plan kitchens place higher demands on secure installation to minimize noise and service calls. For countertop or cabinet-mounted GE and Hotpoint models, material choice, corrosion resistance, and fastener compatibility determine how well the bracket preserves fit and function over time without introducing stress to the appliance frame or surrounding cabinetry.

Quick Overview

| Feature | Details |

|---|---|

| Product type | Replacement mounting bracket kit (2-pack) for dishwasher installation |

| Compatible models/series | Designed for GE/Hotpoint countertop and cabinet dishwasher brackets including CDT8, GDF4, GDT5, HDF3 series and other compatible models; replaces WD01X27759 and related part numbers |

| Material & finish | 304 stainless steel with galvanized finish; zinc-coated screws included |

| Included components | 2 mounting brackets + 4 zinc-coated screws |

| Mounting type / installation | Countertop mount / cabinet installation support with pre-drilled holes |

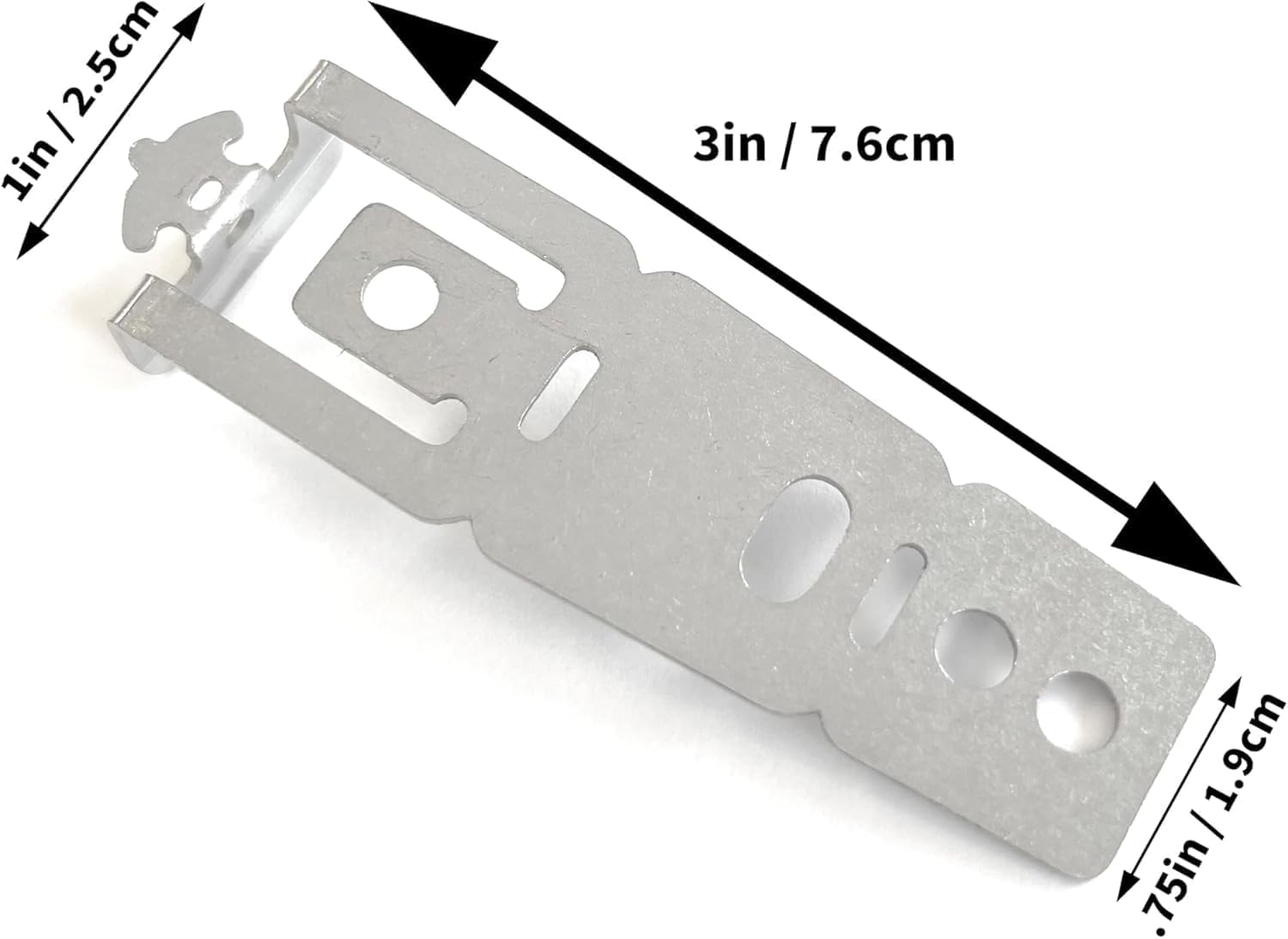

| Dimensions | 3.34 x 0.99 x 0.52 inches per bracket |

| Item weight | 1.44 ounces (per listing) |

| Finish type | Unfinished / galvanized finish |

| Warranty | Not specified by listing |

This bracket kit translates manufacturer compatibility and corrosion-resistant materials into practical stability for countertop and cabinet-mounted dishwashers. The small footprint and pre-drilled mounting holes indicate straightforward mechanical attachment that secures appliance edges and aligns mounting points; included screws reduce the need to source fasteners separately, which benefits replacement scenarios and basic installation tasks in typical household kitchens.

Cleaning performance and spray coverage implications

The mounting bracket is an indirect but relevant element for cleaning performance because a secure chassis helps maintain stable spray-arm geometry and correct drain alignment, both important for full wash coverage. When a dishwasher is firmly mounted and level, spray arms are less prone to wobble or misalignment that can create blind spots or uneven water distribution, and stable drainage prevents backflow or pooling that can undermine cycle effectiveness. For countertop-mounted GE and Hotpoint units, a bracket that resists loosening under vibration will reduce the likelihood of intermittent misalignment over repeated cycles; the 304 stainless steel construction and included screws aim to preserve tight mounting points and consistent internal hydraulics without altering wash technologies within the machine.

Spray-arm alignment and mechanical stability

Spray-arm performance depends on consistent rotational clearance and pressure from the pump; any lateral movement of the tub relative to the mounting frame can change spray trajectories. A dedicated bracket that secures the appliance to the countertop or cabinet minimizes chassis flex and micro-movements during the high-pressure portions of cycles. In practice, a corrosion-resistant bracket that maintains a rigid connection over time supports repeatable spray-arm motion and reduces the chance of localized cleaning failures. Properly sized fasteners and pre-drilled hole alignment reduce the risk of over-torquing or mispositioning that could transfer stress to internal components.

Drain, inlet alignment, and water flow considerations

Correct drain and inlet routing requires predictable chassis positioning; if the dishwasher shifts, hoses can develop kinks or predistorted angles that impact flow rates and fill/empty cycles. A mounting bracket that keeps the appliance flush against the mounting surface helps ensure that hoses maintain manufacturer-recommended paths, which supports designed water exchange and reduces potential for standing water. While the bracket does not change pump capacity or filtration, its role in preserving alignment contributes to consistent hydraulic conditions essential for full wash coverage and reliable cycle completion.

Capacity, rack clearance, and installation height impact

Although the WD01X27759 bracket does not alter internal rack design or stated place settings, installation height and flush mounting affect how racks load and clear the countertop or nearby cabinetry. Countertop-mounted installations commonly rely on precise bracket spacing to keep the door and racks from contacting counters or cabinet faces; a bracket with correct thickness and repeatable placement helps maintain the intended clearances for tall glasses and larger cookware. For households that load a mix of dish sizes, consistent vertical space and level mounting translate to predictable rack geometry and fewer loading compromises. The small form factor of this bracket suggests minimal intrusion into clearance while providing mechanical support to preserve the manufacturer’s intended interior volume and rack travel.

Installation height tolerances and rack clearance

Dishwasher designers allocate headroom for upper racks and spray patterns; small variations in installation height can force consumers to adapt by rearranging rack positions or limiting item sizes. A robust replacement bracket that matches OEM mounting points helps restore the original vertical placement, which is especially important after service or cabinet modifications. Because the bracket dimensions are compact, it performs as a precision spacer; precise hole placement and fastener selection ensure the unit returns to OEM alignment, preserving intended rack travel distances and reducing the need to alter loading patterns for everyday items.

Countertop mount specifics for place-settings and ergonomics

Countertop-mounted units are commonly used where undercounter space is limited; securing such appliances requires brackets that prevent forward or lateral movement when racks extend. The WD01X27759 kit includes zinc-coated screws to fasten the bracket securely and mitigate movement during loading and unloading. Stable mounting preserves ergonomics at the countertop edge, reducing the likelihood that heavy or awkward items will shift the appliance during use. For users prioritizing capacity and convenient loading, an accessory that reinstates OEM mounting geometry helps maintain the expected place-setting compatibility without sacrificing access.

Noise levels and open-kitchen suitability

Noise perception in kitchens derives from motor and pump emissions amplified by cabinet resonance and vibration coupling into counters. A mounting bracket functions as a mechanical interface that can either attenuate or exacerbate noise transfer depending on material stiffness and attachment quality. The 304 stainless steel bracket with a galvanized finish provides rigid support intended to reduce chassis movement; when correctly installed with appropriate fastener torque, that rigidity can lower secondary noise generated by rubbing or micro-shifts. In open-plan kitchens where ambient sound and low-frequency vibration are more noticeable, retaining firm attachment points is a practical measure to reduce the contribution of mechanical looseness to overall operational noise.

How solid mounting reduces vibration-related noise

Vibration-related noise often results from relative movement between the dishwasher cabinet and mounting surface; repeated cycles can loosen connections and increase rattles. A durable bracket assembly keeps contact points stable, limiting the mechanical paths through which vibration transmits to adjacent cabinetry. The combination of 304 stainless steel strength and properly sized screws targets the reduction of resonant joints, translating to fewer intermittent rattles and a cleaner acoustic profile during high-speed pump operation. While the bracket cannot change manufacturer-rated decibel levels, it influences perceived noise by eliminating installation-borne amplification.

Sound insulation and placement considerations for open layouts

Even with a stable bracket, kitchen placement and neighboring materials affect perceived noise: thin cabinetry panels and hollow walls amplify vibrations more than dense or damped structures. Installation that pairs a rigid bracket with recommended cabinet materials, or adds non-metallic washers or isolation pads at contact points, can reduce high-frequency rattles and low-frequency transmission. For open-plan layouts, securing the appliance with corrosion-resistant brackets that resist loosening ensures the mounting interface remains consistent over time, which supports ongoing noise control efforts and maintains a quieter kitchen environment.

Drying performance, moisture control, and venting alignment

Drying systems are influenced by internal airflow and door/vent positioning; external mounting that shifts the appliance can alter vent clearance or the angle of moisture discharge. A bracket that preserves OEM alignment helps maintain the designed path for air and vapor during drying cycles, supporting effective condensation management and vent operation. The bracket’s corrosion-resistant finish reduces risk of rust-related debris that could obstruct vents or drip pathways over time. While the accessory does not alter the dryer type (heated, condensation, or fan-assisted), keeping the dishwasher secured prevents subtle changes in vent gaps and door sealing that might otherwise exacerbate moisture accumulation around the cabinet opening.

Bracket effect on venting, door seal, and condensation control

Door seals and vent openings require precise alignment to the cabinet face; when the dishwasher is vertically or laterally displaced, gaps can enlarge and change airflow patterns, potentially directing moisture toward sensitive cabinetry. A replacement bracket that maintains consistent positioning preserves the intended radial clearance for vents and the compression profile of door gaskets. This alignment supports the manufacturer’s drying strategy by minimizing unplanned airflow paths and reducing the potential for condensation to collect on adjacent surfaces. Properly fastened metal brackets with corrosion resistance help avoid later-stage buildup that could interfere with vents.

Moisture pathways and material compatibility near cabinetry

Galvanized finish and 304 stainless steel resist corrosion in moist environments, reducing the chance that bracket deterioration will deposit particulates that attract moisture or impede vent openings. Selecting fasteners with compatible coatings reduces galvanic action against cabinet hardware and protects surrounding woodwork from staining or accelerated wear. For installations where drying efficiency is a priority, a bracket that remains dimensionally stable under humid conditions contributes to predictable moisture management at the appliance–cabinet interface.

Durability, maintenance, and long-term reliability

Long-term reliability of mounting hardware depends on material choice, coating integrity, and correct fastener pairing. The WD01X27759 bracket is specified as 304 stainless steel with a galvanized finish and ships with zinc-coated screws, a combination aimed at resisting corrosion and wear in humid kitchen environments. Durability is reinforced by pre-drilled holes that reduce the likelihood of improper hole-making during replacement, and the inclusion of screws simplifies matching fastener sizes to the bracket’s geometry. Regular inspection of mounting points for looseness or corrosion and periodic retorquing to manufacturer torque specifications are standard maintenance practices that will preserve bracket function and reduce stress transmission to the dishwasher frame over time.

Corrosion resistance and mechanical wear considerations

304 stainless steel offers robust resistance to oxidation in household conditions and is commonly specified for kitchen hardware that encounters moisture. The galvanized finish provides an additional protective layer, while zinc-coated screws complement the corrosion strategy by reducing the risk of fastener failure. Over prolonged exposure to detergents, heat, and humidity, coatings can degrade; selecting compatible cleaning practices and avoiding abrasive chemicals near mounting points helps maintain protective finishes. In repair scenarios, matching the screw type and thread engagement depth prevents overloading the bracket holes and maintains structural integrity.

Serviceability, replacement cycles, and who should avoid this accessory

This bracket kit targets consumers needing a direct replacement for specific GE and Hotpoint mounting points; it is not a universal mounting system and may not suit non-compatible chassis geometries or heavily modified countertop installations. Users with nonstandard or custom cabinetry, unusually thick countertops, or appliances outside the listed compatibility should verify hole spacing and bracket thickness before installation. Those expecting vibration damping through flexible mounts should note this kit emphasizes rigid attachment rather than isolation. Regular inspection and basic maintenance—checking fastener torque and corrosion—extend service life, while replacement cycles hinge on installation environment and household usage patterns.

Pros & Cons

Pros

- Corrosion-resistant construction: The use of 304 stainless steel and a galvanized finish provides strong resistance to rust and oxidation in typical kitchen environments, which supports long-term dimensional stability and appearance. This material choice reduces the likelihood of metal degradation near moisture and detergent exposure.

- OEM compatibility: Listed compatibility with GE and Hotpoint models and replacement part numbers simplifies sourcing for consumers replacing original brackets, reducing the risk of incorrect fit during routine repairs or post-service reassembly.

- Complete kit with screws: Inclusion of zinc-coated screws removes the need to source fasteners separately and ensures the screw material is compatible with the bracket’s corrosion protection strategy, aiding correct installation.

- Compact dimensions: A small footprint (3.34 x 0.99 x 0.52 inches) minimizes intrusion into cabinet or countertop clearances while providing necessary support for mounting points, preserving rack clearance and door travel.

- Pre-drilled holes for straightforward alignment: Factory-drilled holes reduce on-site modification and help maintain correct hole spacing, which supports repeatable alignment with OEM mounting points and reduces installation error.

- Stiffness for vibration control: Rigid stainless-steel construction helps limit tub movement that can amplify vibration-related noise, contributing to a more stable operation when properly installed.

Cons

- Not a universal solution: The bracket is designed for specific GE/Hotpoint series and related part numbers; users with nonmatching hole patterns or custom cabinetry may find it incompatible without modification.

- Rigid mounting only: The product focuses on secure attachment rather than vibration isolation; households seeking acoustic damping through flexible mounts or vibration pads will need additional components.

- Limited documentation and warranty details: Listing information does not specify a warranty or extensive installation guidance, which may concern consumers who prefer documented OEM backing or need step-by-step instructions.

- Small hardware size: The compact form factor suits many installations but may be insufficient in unique situations that require larger or reinforced support brackets for modified countertops or nonstandard load paths.

Final Verdict: Who This Dishwasher Accessory Is Best For (and Who Should Skip It)

The WD01X27759 two-pack mounting bracket kit is best suited for households that need a straightforward, corrosion-resistant replacement for OEM dishwasher mounting points on compatible GE and Hotpoint countertop or cabinet-mounted models. It benefits users focused on restoring original alignment, reducing installation-borne vibration, and preserving spray-arm geometry and drainage alignment that support consistent cleaning results. The included zinc-coated screws and pre-drilled holes simplify reinstallation after service, making this kit practical for routine replacement scenarios where the original bracket has corroded or been damaged.

This product is not ideal for kitchens requiring vibration isolation, custom cabinetry with nonstandard mounting geometries, or installations that need reinforced structural brackets for altered countertops. Consumers who require documented warranty coverage or step-by-step manufacturer installation instructions may need to verify support options before purchase. Compared to similar replacement brackets, the material selection and included hardware position this kit as a practical OEM-aligned option for maintaining stability and preserving the intended mechanical interfaces of compatible dishwashers in typical household settings.

Frequently Asked Questions (FAQs)

Will these brackets fit any GE or Hotpoint dishwasher model?

The brackets are specified for compatibility with a range of GE and Hotpoint countertop and cabinet-mounted series (including CDT8, GDF4, GDT5, HDF3 and similar models), and they replace listed part numbers such as WD01X27759. Compatibility depends on matching OEM hole spacing and mounting geometry; verify the appliance’s mounting points against bracket dimensions before installation to ensure a proper fit.

Can these brackets reduce dishwasher noise in an open-plan kitchen?

A rigid, properly installed mounting bracket can reduce noise by limiting chassis movement and minimizing vibration coupling into cabinetry. While the bracket does not change the dishwasher’s manufacturer-rated decibel output, it helps prevent installation-borne rattles and resonant amplification that make machines sound louder in open layouts.

Are the included screws suitable for all installation surfaces?

The kit includes zinc-coated screws intended to match the bracket’s corrosion protection; these fasteners are suitable for standard wood or cabinet materials. For atypical substrates like metal framing, stone countertops, or custom mounting scenarios, selecting specialized fasteners compatible with the substrate material and load conditions is recommended.

Does the bracket affect dishwasher drying or ventilation?

The bracket’s primary role is mechanical support and maintaining OEM alignment. By preserving correct door and vent clearances, it helps maintain intended drying airflow paths and reduces the chance that shifted alignment will direct moisture in unintended ways. The bracket itself does not alter the internal drying system or prescribed venting method.

How durable is the 304 stainless steel and galvanized finish in kitchen environments?

304 stainless steel is commonly specified for kitchen hardware due to its strong resistance to oxidation and corrosion under normal household conditions. A galvanized finish and zinc-coated screws add further protection. Regular visual inspection and avoiding abrasive chemicals near the mounting points will help maintain coating integrity and mechanical durability over time.

Should vibration isolation be used instead of these brackets to control noise?

This bracket emphasizes rigid attachment to restore OEM alignment and limit chassis movement; it does not provide vibration isolation. For installations where acoustic damping is a priority, vibration isolation pads or flexible mounts used in conjunction with secure brackets can help balance stability and noise control, but those components are separate from this kit.

Is professional installation required for these mounting brackets?

The brackets feature pre-drilled holes and include screws to simplify replacement, which can facilitate DIY installation by a competent homeowner. However, if the cabinet or countertop requires modification, or if there is uncertainty about correct torque, alignment, or plumbing connections, professional installation is recommended to avoid damage to the appliance or surrounding cabinetry.

What maintenance is recommended for long-term bracket performance?

Periodic inspection of fastener torque and visual checks for corrosion or coating wear are advisable. Retorquing to manufacturer-recommended torque values and replacing screws if coatings degrade will preserve mechanical integrity. Avoiding harsh chemicals and ensuring the area around vents and seals remains clean will also help the bracket and adjacent materials remain serviceable.